Bubuk Poliakrilamida Kationik Limbah Air

Merek Jiufang

produk asal Kota Shenyang

waktu pengiriman Waktu tunggu: 7 hari

kapasitas pasokan 2000Metrik Ton per Bulan

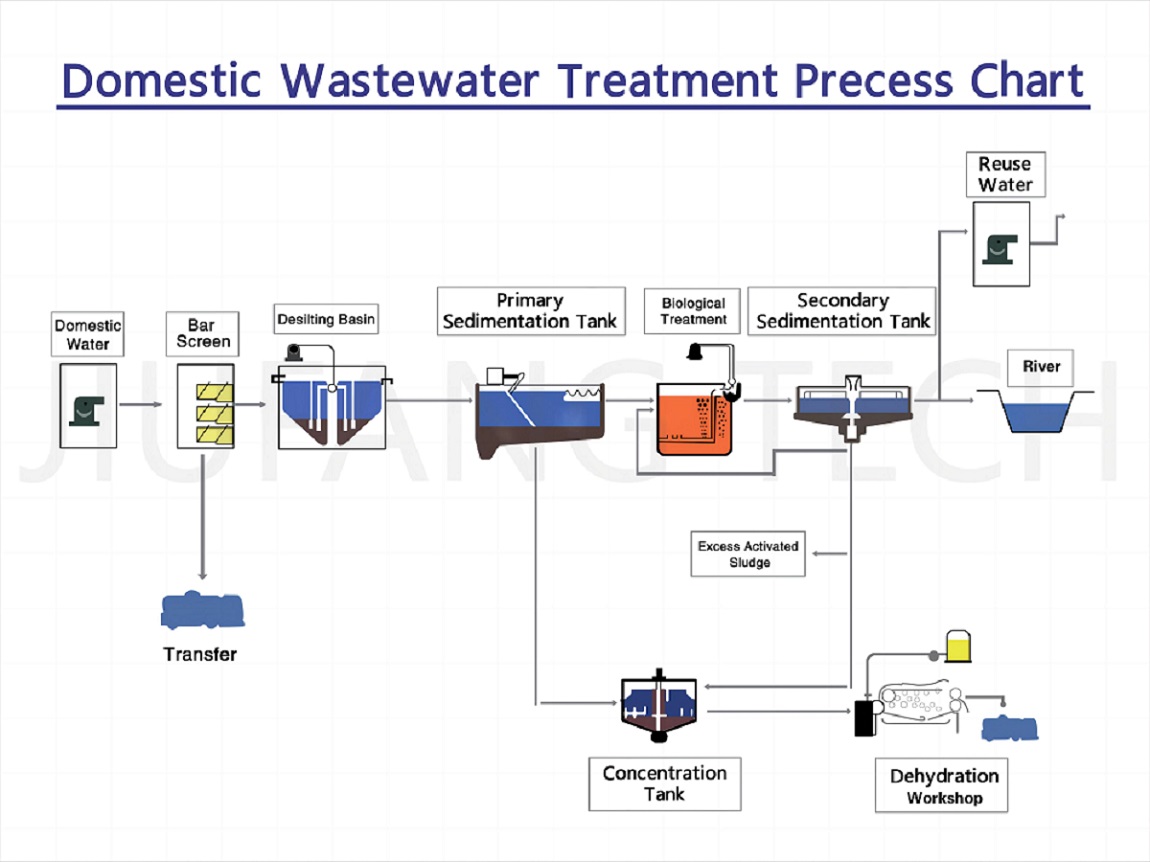

1.Poliakrilamida kationik untuk pengolahan air limbah digunakan dalam mesin pengering untuk mengurangi lumpur.

2. Perusahaan kami telah bekerja sama dengan lebih dari 300 STP dalam bisnis kimia PAM untuk pengolahan air.

3.Pengolahan air flokulan poliakrilamid berarti menggunakan poliakrilamid untuk pengolahan di STP.

Download

Cationic polyacrylamide for wastewater treatment is an important PAM chemical for water treatment and is used in dewatering machine to reduce the excess sludge in STP.

Cationic polyacrylamide powder is widely used chemical which is made by acrylamide with DAC or DMC copolymering or homopolymering. Polyacrylamide flocculant water product is main chemical in the biochemical treatment process.

The principle of cationic polyacrylamide flocculant water treatment mainly includes the following aspects:

1. Electrical neutralization is carried out using cationic polyacrylamide powder

The surface of sludge particles usually carries negative charges, while cationic polyacrylamide will generate positively charged ionic groups after dissolving in water. When cationic polyacrylamide powder is added to the sludge, the positively charged ions are mutually attracted to the negative charges on the surface of the sludge particles, resulting in electrical neutralization. This electrical neutralization weakens the electrostatic repulsion between the sludge particles, thereby promoting the particles to approach each other and coagulate together.

2. Adsorption bridging

Cationic polyacrylamide powder for wastewater treatment has long molecular chains that fully extend in water. These molecular chains of cationic polyacrylamide for wastewater treatment can adsorb multiple sludge particles simultaneously, just like building bridges between the particles. As more particles are adsorbed onto the molecular chains, larger flocs gradually form. This adsorption bridging effect can bridge the distance between the particles, connecting the originally dispersed sludge particles to form larger and easier-to-settle flocs.

3. Sweeping and entrapment

When the flocs formed by polyacrylamide powder for wastewater treatment gradually increase in size, they will sweep the surrounding tiny particles like a broom during the sedimentation process and wrap them inside the flocs. At the same time, larger flocs will also capture those particles that have not been directly adsorbed or bridged like a net, further enhancing the flocculation effect. This sweeping and entrapment effect enables more sludge particles to be incorporated into the flocs, improving the efficiency and thoroughness of flocculation.

In conclusion, cationic polyacrylamide flocculant water treatment effectively flocculates sludge through mechanisms such as electrical neutralization, adsorption bridging and sweeping and entrapment, transforming it from a dispersed state to larger flocs for subsequent separation and treatment.

Industry-specific attributes:

Industry-specific attributes:

| Name | Cationic polyacrylamide powder | |||

| Application | PAM chemical for water treatment | |||

| CAS NO. | 9003-05-8 | |||

Other Attributes:

| Appearance | Cationic polyacrylamide powder | |||

| Solid Content | 90% | |||

| Molecular Weight 10*6 | 8~9 | |||

| Density(25℃) | 0.75g/cm3 | |||

| PH Value(1% water solution) | 6~8 | |||

| Cationic Charge | 70% | |||

| Dissolving Time,min | <30 | |||

| Storage Temperature,℃ | 0~35 | |||

| Shelf Life,month | 24 | |||

Supply Ability:

| Supply Ability | 2000Metric Tons per Month | |||

Lead Time:

| Kuantitas (kilogram) | 1~50 | >50 | |

| Waktu tunggu (hari) | 7 | dinegosiasikan | |